"Real Time" Continuous Efficiency Control with The Boiler Consultant™ Performance Modeling Control System

|

"Real Time" Continuous Efficiency Control with The Boiler Consultant™ Performance Modeling Control System |

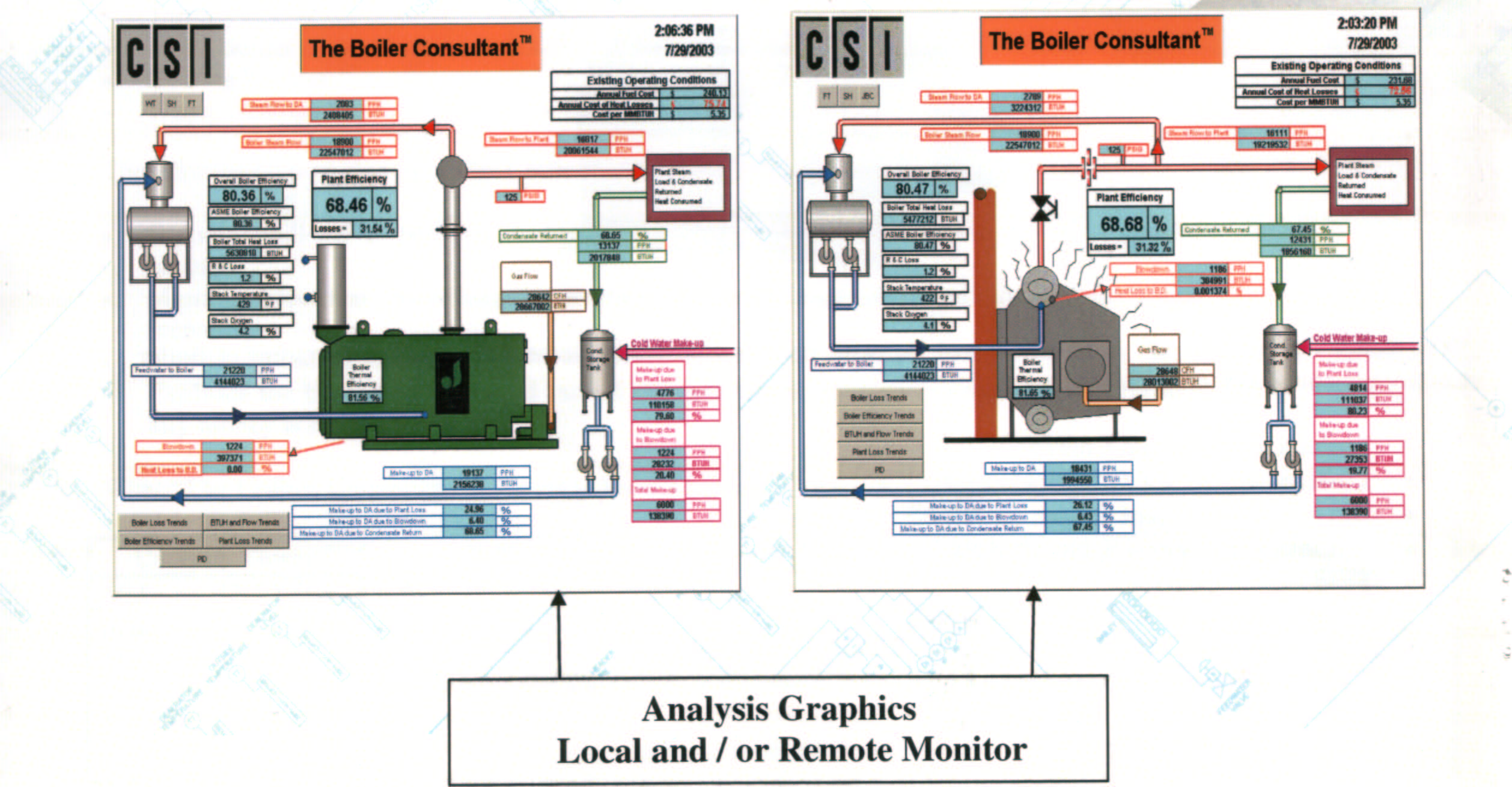

"Real Time" Continuous Efficiency Control with The Boiler Consultant™ Performance Modeling Control System, a PLC based continuous Energy Management tool for identifying and eliminating energy waste through investment-based maintenance, forecasting and control. The Boiler Consultant™ continuously calculates and displays existing facility efficiencies while controlling the appropriate associated process components.

The Boiler Consultant™ (TBC) Control Functions such as Burner Management, Combustion Control, TBC EzTrim™ O2/CO Trim Control, Cross Limiting and 1, 2 or 3 Element Level Control are accomplished in the foreground while ASME PCT is running continuously in the background.

Standard features include "Real Time" display and trending of measured and unmeasured (modeled and/or calculated) variables, time stamping of alarm events, complete heat balance and modeling for predictive savings in several formats: BTU's, mass flow, dollars wasted, dollars saved, etc. The Boiler Consultant™ communicates via Modbus and Ethernet with your existing equipment and/or our DCS or DAS Modeling software.

Accessing The Boiler Consultant™ Performance Modeling mode allows management to manipulate multiple on-screen conditions to demonstrate and evaluate resultant Efficiency and Control performance of contemplated changes prior to making